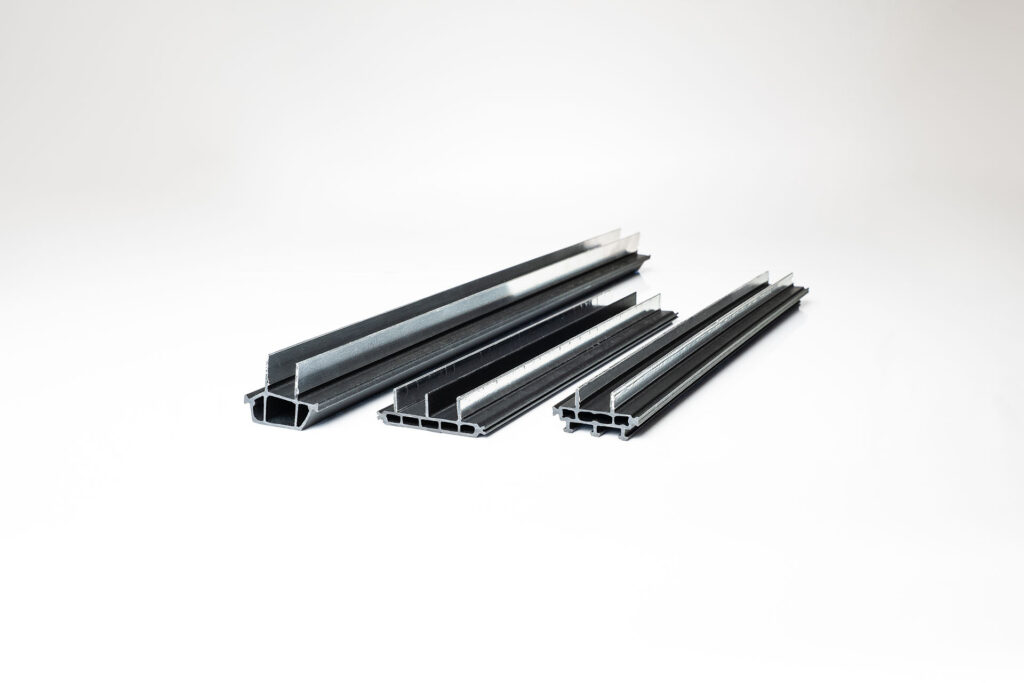

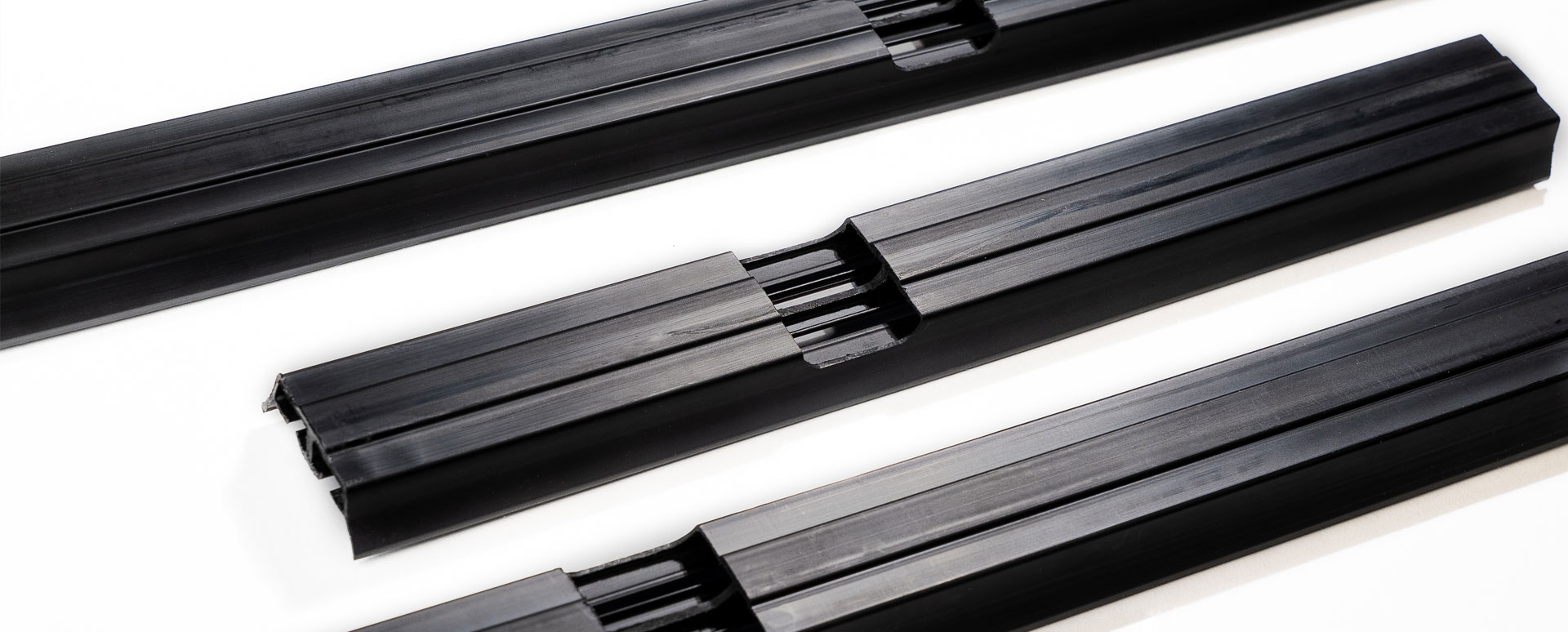

Mechanical and accessory machining

Alfa Solare is able to supply not only the extruded product, but also a wide range of accessory mechanical processing. In this way the extruded product is transformed into a finished component, by the execution of assembly as well.

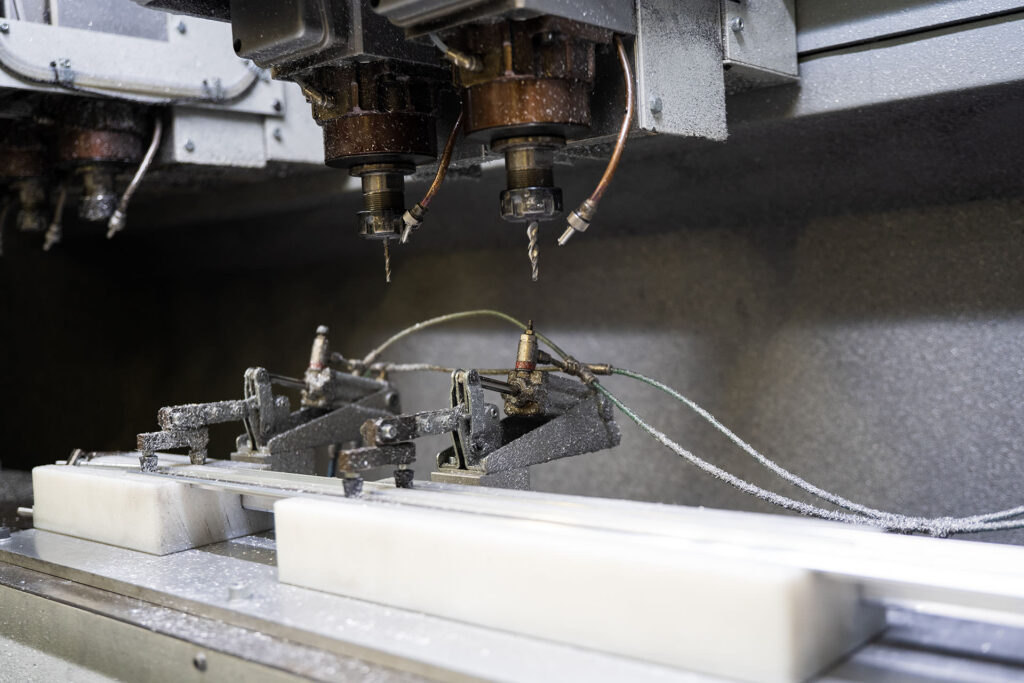

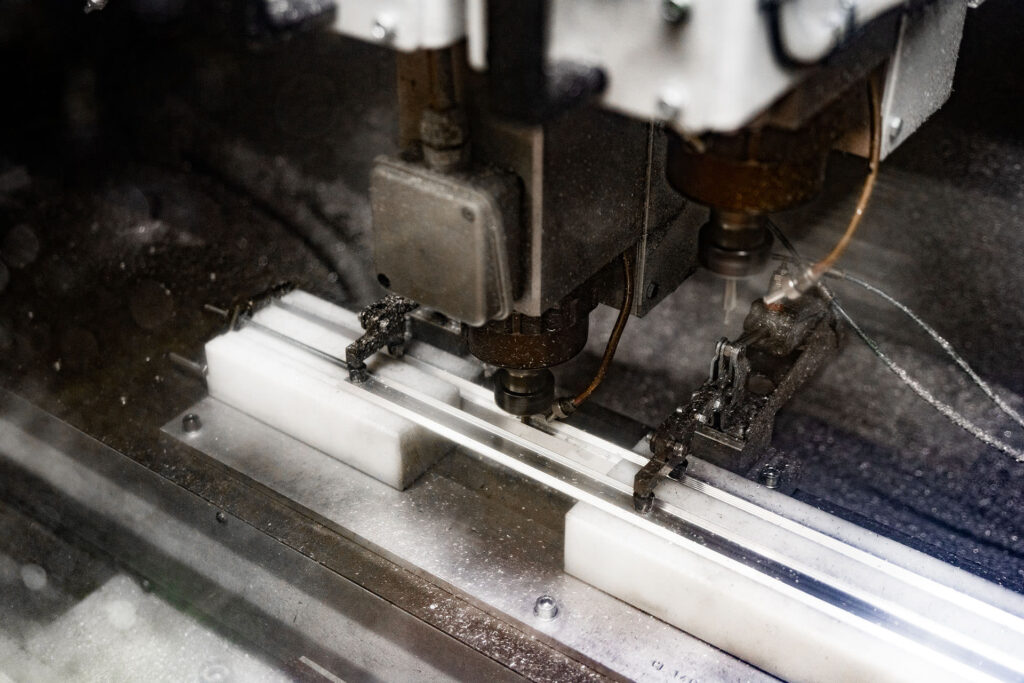

We can machine parts up to 6.5 meters long and perform complex machining up to five axes, with very tight tolerances.

Machining can be performed in-line or on machining machines.

In-line machining processes are:

- Drilling

- Grooving

- Milling

- Cutting to length

Off-line machining processes are:

- Angle cutting

- Blanking

- CNC machining of all kinds

- Assembly

- Miling

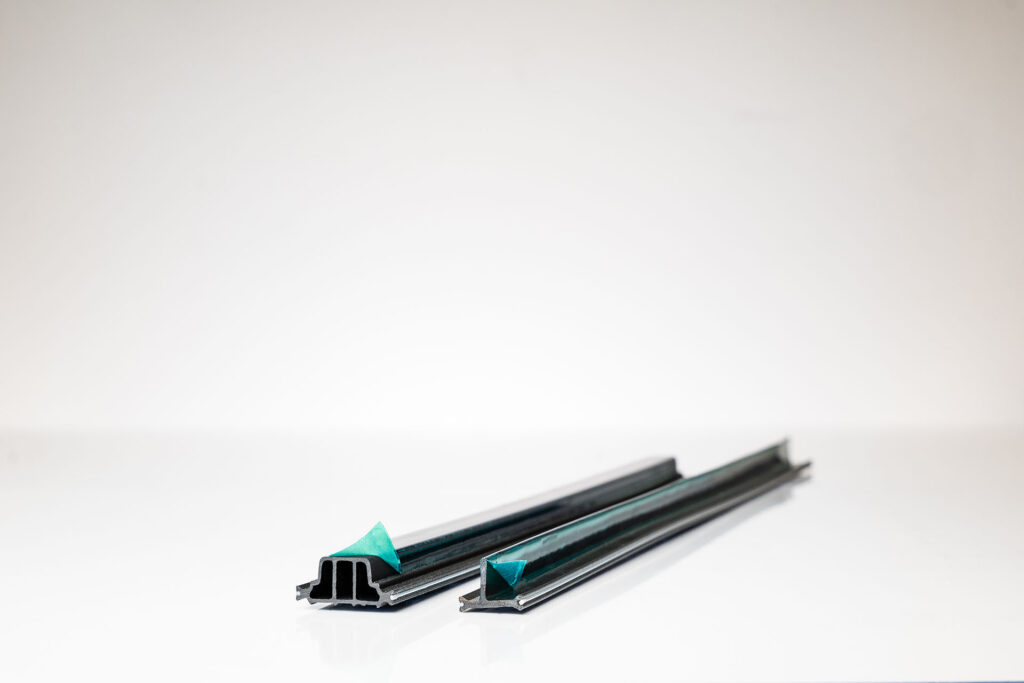

In addition, in terms of accessory processing, Alfa Solare can supply the profiles with:

- Heat-sealable glue wire

- Removable protective film

- Double-sided adhesive

- Peelable and primer

- Certified low-emissivity aluminum foil

- Customization with marking (logo, production date, batch, etc.)

- Custom coloring on all product ranges

- Customized packaging